Evonik to expand its competencies in 3D printing with research cooperation

- Development work for “ready-to-use” radiation-curing resin systems for 3D printing to be presented for the first time

- Partnership with Cubicure paves the way for industrial component manufacturing via 3D printing

- Development of custom-made specialty chemical components for the next generation of materials

Evonik and Cubicure, a spin-off company of Vienna University of Technology, have entered into a cooperative agreement to jointly develop innovative radiation-curing resin systems. The partnership with the start-up company is managed by Creavis, the strategic innovation unit of the specialty chemicals group.

“The Hot Lithography technology developed by Cubicure is an interesting option for manufacturing components that meet the exacting standards of industrial applications,” says Prof. Stefan Buchholz, the executive director of Evonik Creavis GmbH. “We have been using this platform for the development of next-generation radiation-curing resin systems for a while. For this purpose, we are developing custom-made components such as oligomers, specialty monomers and suitable additives.”

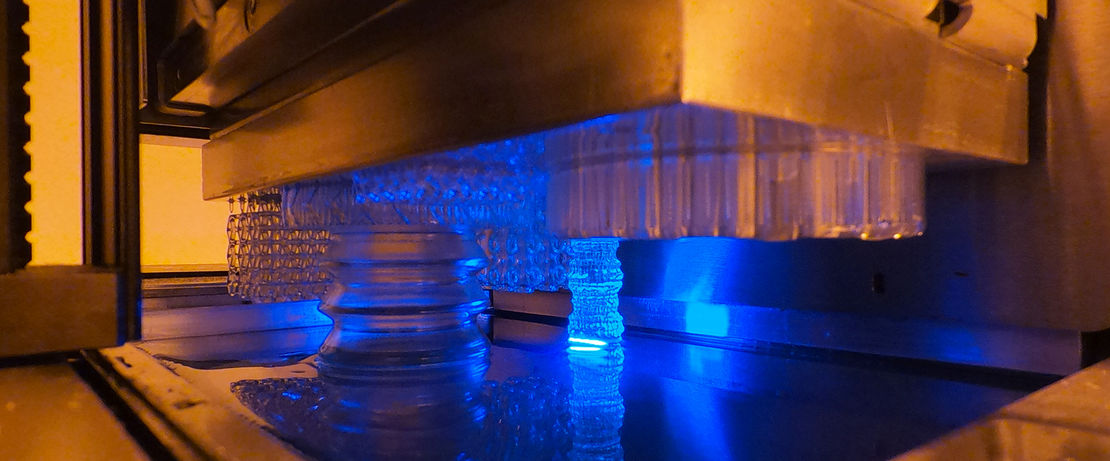

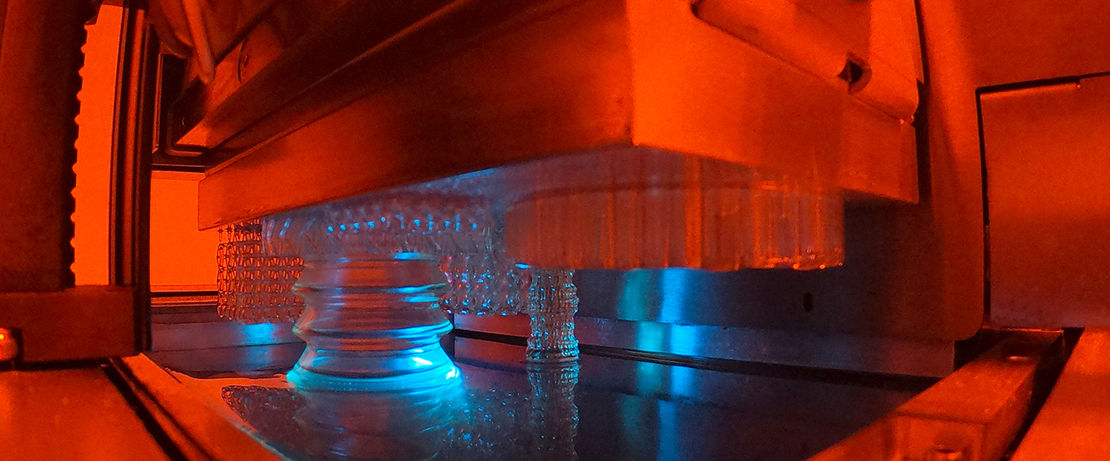

In contrast to conventional stereolithography, Hot Lithography generates objects from a shapeless fluid at higher processing temperatures, using laser-induced polymerization. The approach allows for much greater variability for the components to be processed and enables novel material concepts for manufacturing industrial parts. “Evonik is an outstanding cooperation partner that will accompany and support us in our efforts to create stable and scalable additive production processes,” comments Dr. Robert Gmeiner, CEO of Cubicure.

The development work involving radiation-curing resin systems is part of Evonik’s Additive Manufacturing innovation growth field, in which the company is pooling its 3D printing competencies. “Our strategic focus is on developing and manufacturing ‘ready-to-use’ high-performance materials for all relevant 3D printing technologies. Close cooperation with our customers and partners is a prerequisite for advancing innovations,” explains Thomas Große-Puppendahl, the head of the innovation growth field.

Evonik’s research work on radiation-curing resin systems for additive manufacturing will be on display at the “formnext” tradeshow in Frankfurt/Main in Hall 12.1, Stand C71 from November 19 to 22, 2019.

Company information

Evonik is one of the world leaders in specialty chemicals. The focus on more specialty businesses, customer-oriented innovative prowess and a trustful and performance-oriented corporate culture form the heart of Evonik’s corporate strategy. They are the lever for profitable growth and a sustained increase in the value of the company. Evonik benefits specifically from its customer proximity and leading market positions. Evonik is active in over 100 countries around the world. In fiscal 2018, the enterprise with more than 32,000 employees generated sales of €13.3 billion and an operating profit (adjusted EBITDA) of €2.15 billion from continuing operations.

Evonik’s international activities are organized into six regions. The Asia Pacific North region is headquartered in Shanghai. Sales in Asia Pacific North reached €1.97 billion in 2018. Evonik regards China as one of the driving forces of the global economy and we consequently endeavor to grow our business here. The company now employs over 2,500 employees and has in total of 10 production sites in China.

Disclaimer

In so far as forecasts or expectations are expressed in this press release or where our statements concern the future, these forecasts, expectations or statements may involve known or unknown risks and uncertainties. Actual results or developments may vary, depending on changes in the operating environment. Neither Evonik Industries AG nor its group companies assume an obligation to update the forecasts, expectations or statements contained in this release.